What Is Logistics Planning? Strategies To Save Money And Time

In today’s fast-paced e-commerce environment, efficient logistics planning is the backbone of successful operations. Businesses that master logistics planning gain a competitive edge through reduced costs, faster deliveries, and improved customer satisfaction.

What is Logistics Planning?

Logistics planning is the strategic process of organizing, implementing, and controlling the efficient flow and storage of goods, services, and related information from the point of origin to the point of consumption. It encompasses several key components:

- Transportation Management – Selecting optimal shipping methods, carriers, and routes to move products efficiently.

- Inventory Management – Balancing stock levels to meet demand without excessive warehousing costs.

- Warehousing – Strategic placement and organization of distribution centers and storage facilities.

- Order Processing – Streamlining how orders are received, picked, packed, and shipped.

- Demand Forecasting – Anticipating future needs to prevent stockouts or overstock situations.

Modern logistics planning integrates technology solutions like Transportation Management Systems (TMS), Warehouse Management Systems (WMS), and real-time tracking to create a cohesive supply chain strategy.

Benefits of Logistics Planning

Effective logistics planning delivers substantial advantages for e-commerce businesses:

Cost Reduction – Comprehensive logistics planning identifies inefficiencies and eliminates redundant processes. By optimizing transportation routes, consolidating shipments, and negotiating better carrier rates, businesses can reduce transportation expenses by 10-30%. Additionally, proper inventory management prevents carrying costs associated with excess stock, which typically represent 20-30% of inventory value annually.

Enhanced Customer Experience – In today’s market, where 73% of shoppers expect affordable, fast delivery, logistics planning enables businesses to meet these expectations. Well-planned logistics operations lead to faster order fulfillment, accurate delivery estimates, and fewer errors—resulting in higher customer satisfaction and retention rates.

Improved Operational Efficiency – Streamlined logistics processes reduce manual interventions and minimize delays. Businesses implementing integrated logistics planning report 15-25% improvements in warehouse productivity and 20-40% reductions in order processing times.

Adaptability to Market Changes – Robust logistics planning creates flexible systems that can quickly adjust to demand fluctuations, supply chain disruptions, or seasonal variations without significant operational strain.

Environmental Impact – Strategic route planning and load optimization reduce fuel consumption and carbon emissions, supporting sustainability goals while simultaneously reducing transportation costs.

7 Tips for Effective Logistics Planning in E-commerce

1. Implement Data-Driven Demand Forecasting

Modern logistics planning begins with accurate demand prediction. Utilize historical sales data, market trends, and seasonal patterns to forecast inventory needs. Advanced analytics tools can identify patterns that humans might miss:

- Analyze 12-24 months of historical data to identify seasonal trends

- Account for marketing campaigns and promotional events that may spike demand

- Review product lifecycle stages to anticipate natural demand changes

- Update forecasts regularly based on real-time sales data

Businesses using AI-powered demand forecasting report 20-30% lower inventory costs and 15-20% fewer stockouts.

2. Optimize Warehouse Layout and Operations

Warehouse efficiency directly impacts order fulfillment speed and accuracy:

- Position high-velocity products near packing stations to minimize travel time

- Implement slotting optimization to place frequently purchased items together

- Use vertical space efficiently with appropriate racking systems

- Establish clear traffic lanes and workstations to minimize congestion

- Consider implementing zone picking for multi-item orders

A well-designed warehouse layout can reduce picking time by up to 40% and improve order accuracy to 99.5%+.

3. Develop a Multi-Carrier Shipping Strategy

Relying on a single shipping carrier creates vulnerability and limits options:

- Negotiate contracts with multiple carriers based on their strengths in different regions

- Implement rate-shopping technology to automatically select the most cost-effective carrier for each shipment

- Consider regional carriers for certain service areas where they outperform national carriers

- Maintain backup carrier relationships for peak seasons and contingencies

Multi-carrier strategies typically reduce shipping costs by 10-15% while improving delivery performance.

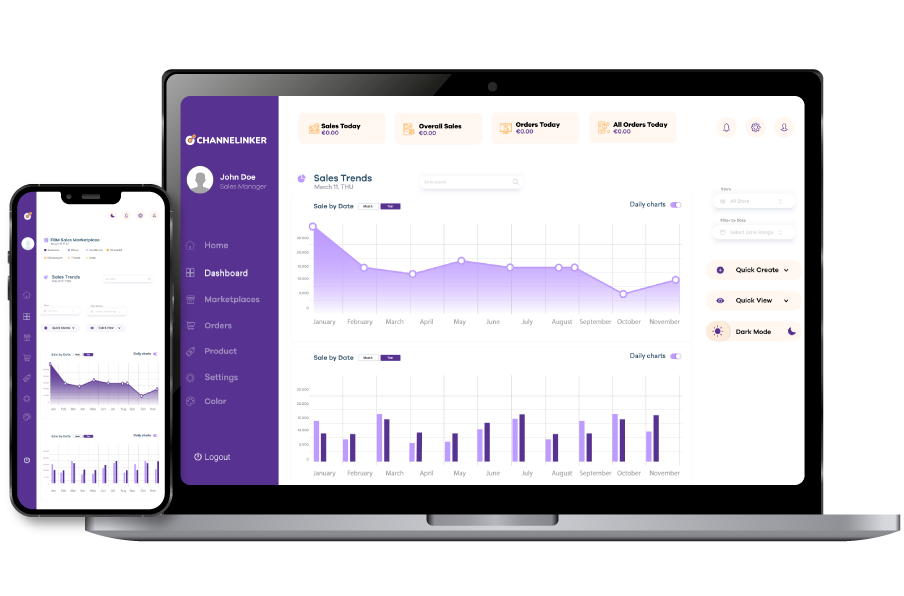

4. Leverage Technology Integration

Modern logistics planning requires seamless technology integration:

- Ensure your e-commerce platform automatically shares order data with your inventory management system

- Implement barcode or RFID tracking for real-time inventory visibility

- Use API connections between your WMS, TMS, and e-commerce platform

- Consider IoT devices for monitoring inventory conditions (temperature, humidity) for sensitive products

- Implement predictive analytics to identify potential disruptions before they occur

Fully integrated logistics technology stacks reduce manual data entry by 90% and processing errors by 80%.

5. Focus on Last-Mile Optimization

The final delivery leg represents 28-53% of total shipping costs:

- Offer multiple delivery options (standard, expedited, same-day) with transparent pricing

- Consider micro-fulfillment centers in high-density markets

- Implement route optimization software to maximize delivery efficiency

- Explore alternative delivery methods like lockers or pickup points

- Provide accurate delivery estimates with real-time tracking

Optimized last-mile logistics can reduce delivery costs by 15-20% while improving on-time delivery performance.

6. Create Contingency Plans

Resilient logistics planning includes preparation for disruptions:

- Identify potential risks throughout your supply chain

- Maintain safety stock for critical products based on lead time variability

- Develop relationships with backup suppliers and carriers

- Document clear procedures for common disruption scenarios

- Conduct regular stress tests of your logistics system

Companies with robust contingency plans recover from disruptions 2-3 times faster than unprepared competitors.

7. Measure and Refine Key Performance Indicators

Continuous improvement requires consistent measurement:

- Track perfect order rate (orders delivered complete, on time, damage-free)

- Monitor inventory turnover ratio by product category

- Measure order cycle time from placement to delivery

- Analyze transportation costs as a percentage of total sales

- Review return rates and reasons

Set benchmark goals for each KPI and review performance weekly or monthly to identify improvement opportunities.

Conclusion

Effective logistics planning is not a one-time exercise but an ongoing process of optimization and refinement. By implementing data-driven demand forecasting, optimizing warehouse operations, developing diverse carrier relationships, integrating technology systems, focusing on last-mile delivery, creating contingency plans, and consistently measuring performance, e-commerce businesses can significantly reduce costs while improving customer satisfaction.

In today’s competitive marketplace, logistics excellence has evolved from a back-office function to a critical competitive advantage. Businesses that invest in comprehensive logistics planning are positioned to outperform competitors through lower operational costs, faster fulfillment, and superior customer experiences.

Logistics Planning FAQ

What is an example of logistical planning?

A practical example of logistics planning is a multi-channel retailer preparing for Black Friday. Their logistics plan would include:

- Increasing warehouse staffing by 40% six weeks before the event

- Positioning high-demand products in easily accessible warehouse locations

- Pre-negotiating surge capacity with primary and backup carriers

- Implementing temporary cross-docking areas to expedite high-volume orders

- Establishing clear communication protocols between customer service and fulfillment teams

- Scheduling staggered promotions to prevent overwhelming warehouse operations

- Setting up real-time inventory visibility across all sales channels

This comprehensive approach ensures the business can handle 5-10x normal order volume without significant delays or errors.

What does a logistics planner do?

A logistics planner orchestrates the movement of products throughout the supply chain by:

- Analyzing transportation options and costs to determine optimal shipping methods

- Coordinating with suppliers on inbound freight scheduling and requirements

- Optimizing inventory placement across distribution networks

- Developing standard operating procedures for warehouse operations

- Negotiating carrier contracts and service level agreements

- Implementing technology solutions for visibility and control

- Creating contingency plans for potential disruptions

- Collaborating with sales and marketing teams to align logistics capacity with promotional activities

- Continuously analyzing performance data to identify improvement opportunities

Effective logistics planners blend analytical skills with practical operational knowledge to create systems that balance cost efficiency with service excellence.

How do you plan a logistics strategy?

Developing a comprehensive logistics strategy involves several key steps:

- Assess Current State: Audit existing processes, technologies, and performance metrics to establish a baseline and identify improvement opportunities.

- Define Clear Objectives: Establish specific, measurable goals aligned with broader business objectives (e.g., reduce shipping costs by 15%, improve on-time delivery to 98%).

- Analyze Customer Requirements: Understand what your customers value most (speed, cost, flexibility) and build your strategy around these priorities.

- Design Network Structure: Determine optimal number and location of distribution centers based on customer concentration and service requirements.

- Select Technology Enablers: Identify and implement systems that provide visibility, control, and automation across your logistics operations.

- Develop Standard Operating Procedures: Create clear processes for all logistics activities from receiving to delivery.

- Establish Performance Metrics: Define KPIs that align with strategic objectives and implement regular reporting cadences.

- Create Implementation Roadmap: Develop a phased approach to logistics improvements, prioritizing high-impact, low-complexity initiatives first.

- Build Continuous Improvement Mechanisms: Establish regular review cycles and improvement processes to ensure ongoing optimization.

The most effective logistics strategies balance service excellence with cost efficiency while maintaining flexibility to adapt to changing market conditions.